Recent Work

The world's fattest spray cap. It offers two types: the 81 MALE cap with a 40-60 cm line width for standard cans and the 81 FEMALE cap with an 81 cm line width for ultra-wide cans. These caps deliver a solid, full-opacity line, increasing coverage speed and surface area. Reusable up to 30 times.

81 Cap

Line width output

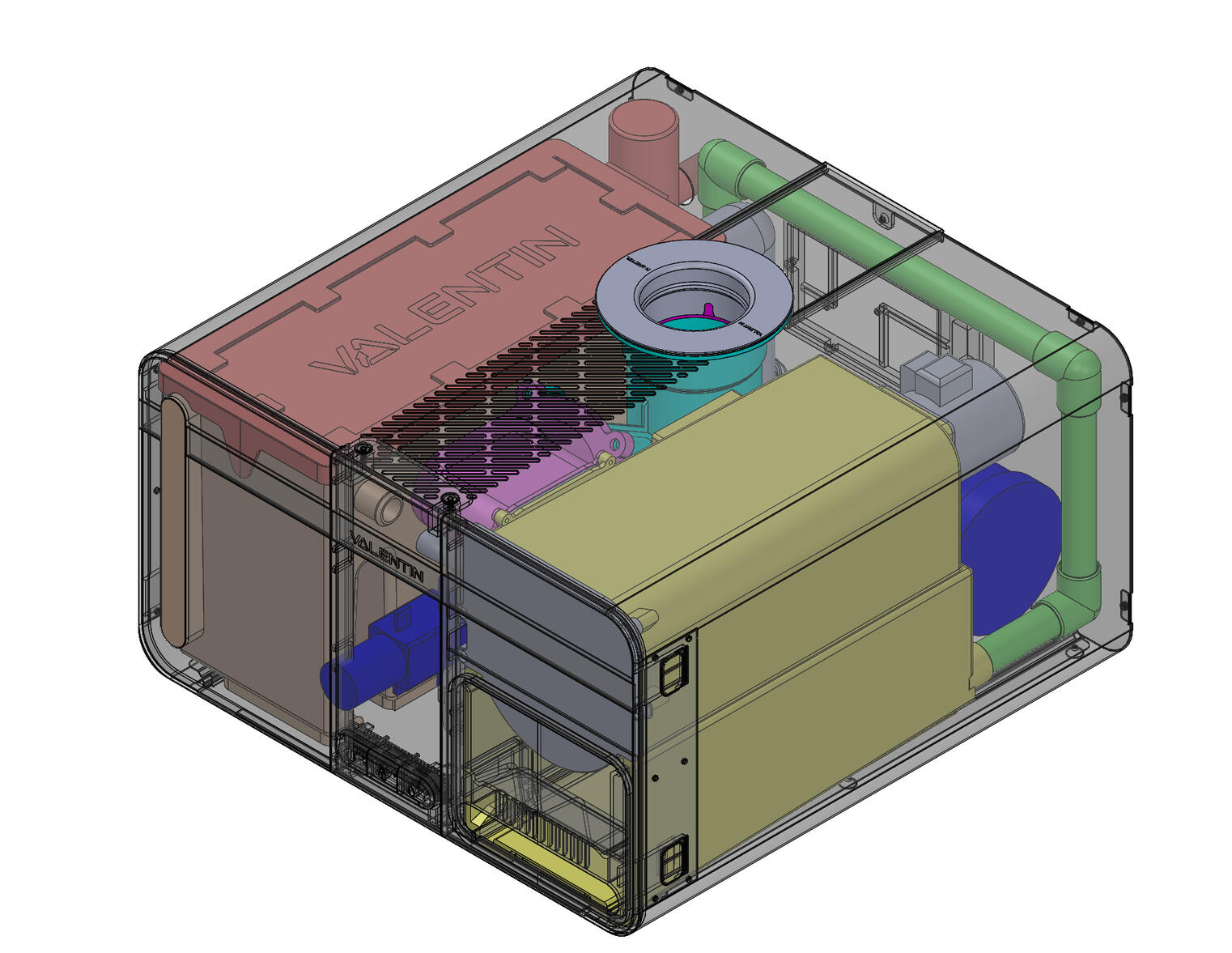

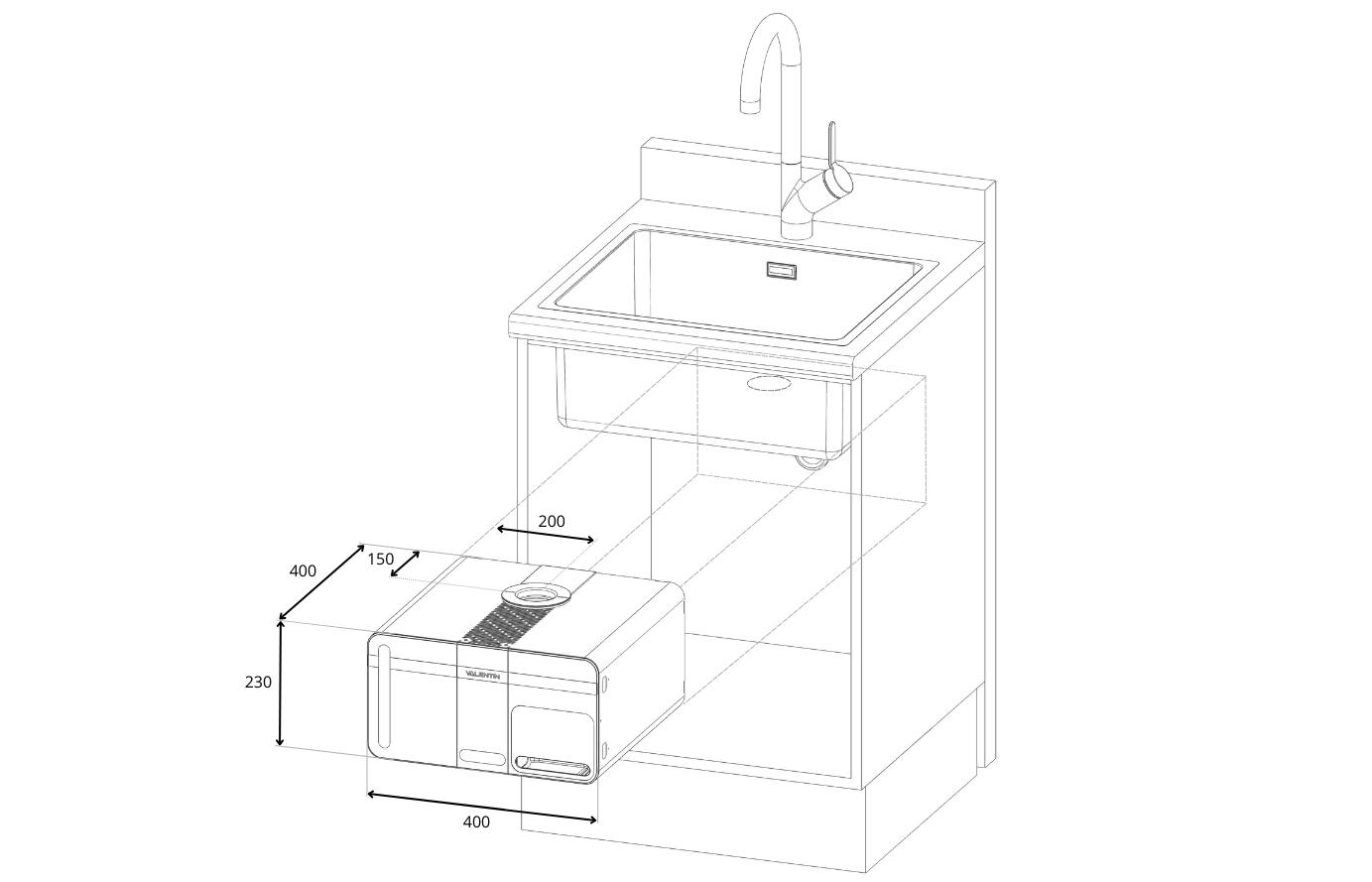

The FGR kitchen appliance is used for easier separation and disposal of inedible parts of food. The appliance is installed in the kitchen cabinet under the kitchen sink, where it is also enlarged with the drain in the kitchen sink and the sewage system. The device automatically separates food waste, water and oil. There are special compartment in the device where food waste is disposed and a second compartment where waste oils are placed.

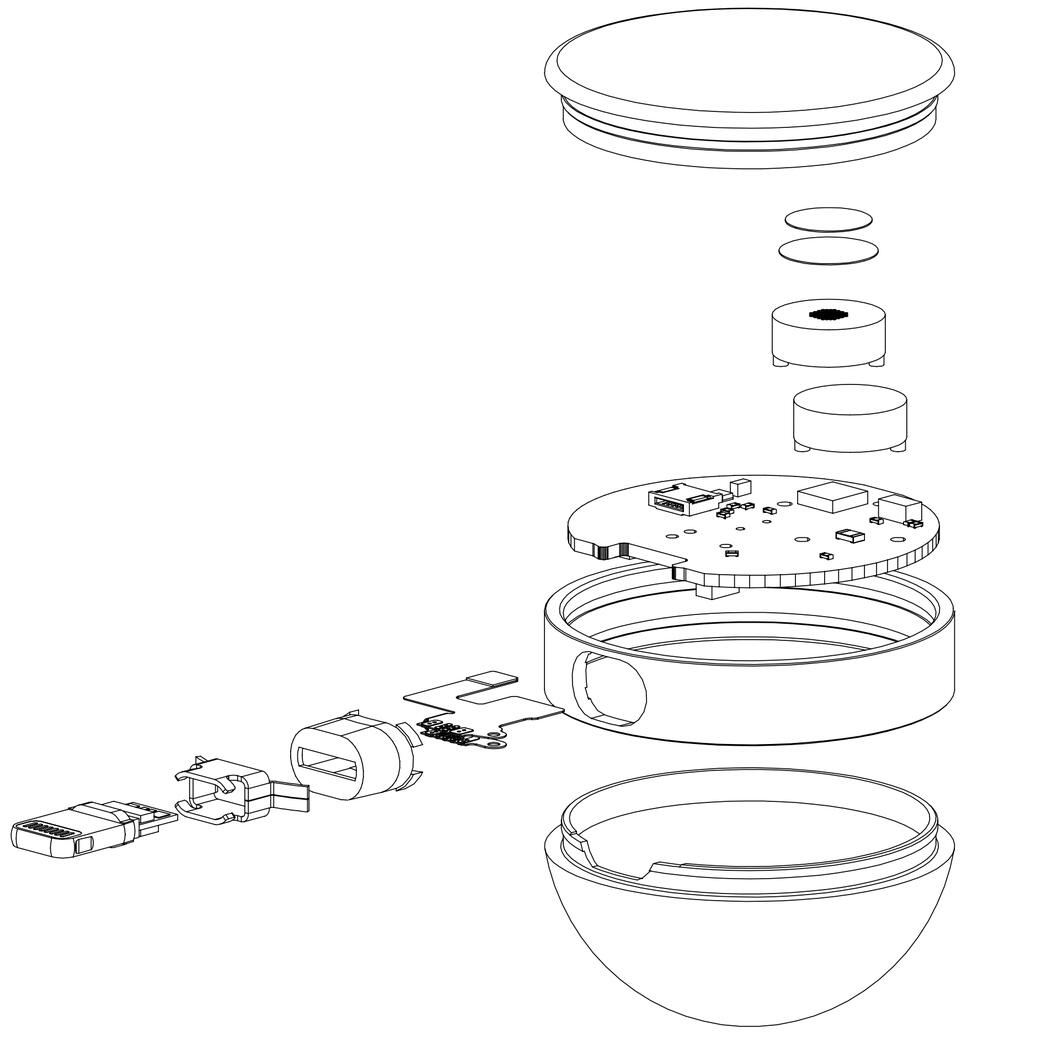

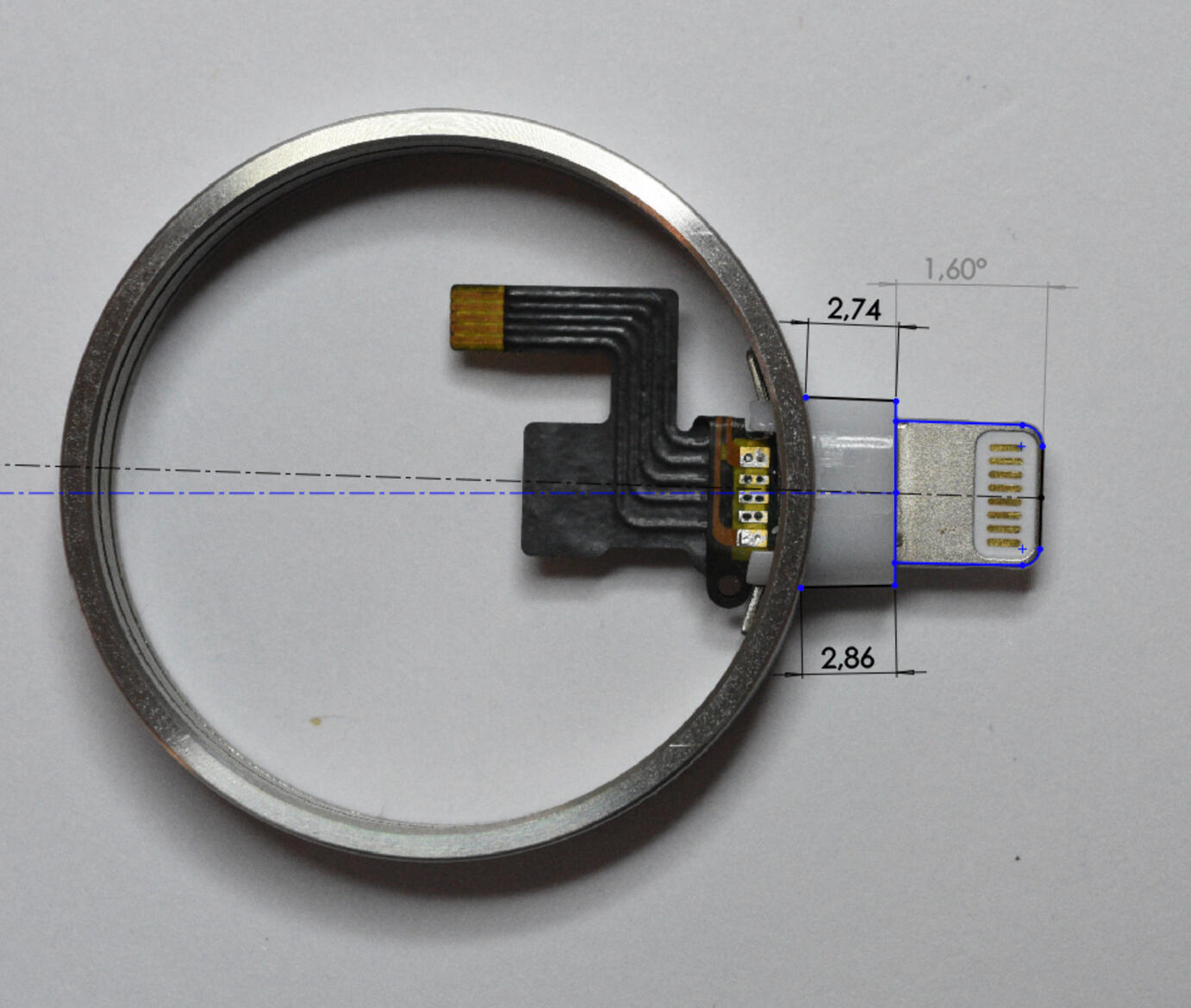

Lumu Power is an easy-to-use digital incident color and light meter that works seamlessly with the free Lumu app to deliver Color Temperature, Illuminance, Spot, Ambient, and Flash Exposure metering functionality on your iPhone.

A new expression of what a light meter can be, Lumu meets the needs of enthusiasts, professionals, and students who find existing light metering solutions too bulky, expensive, and complicated.

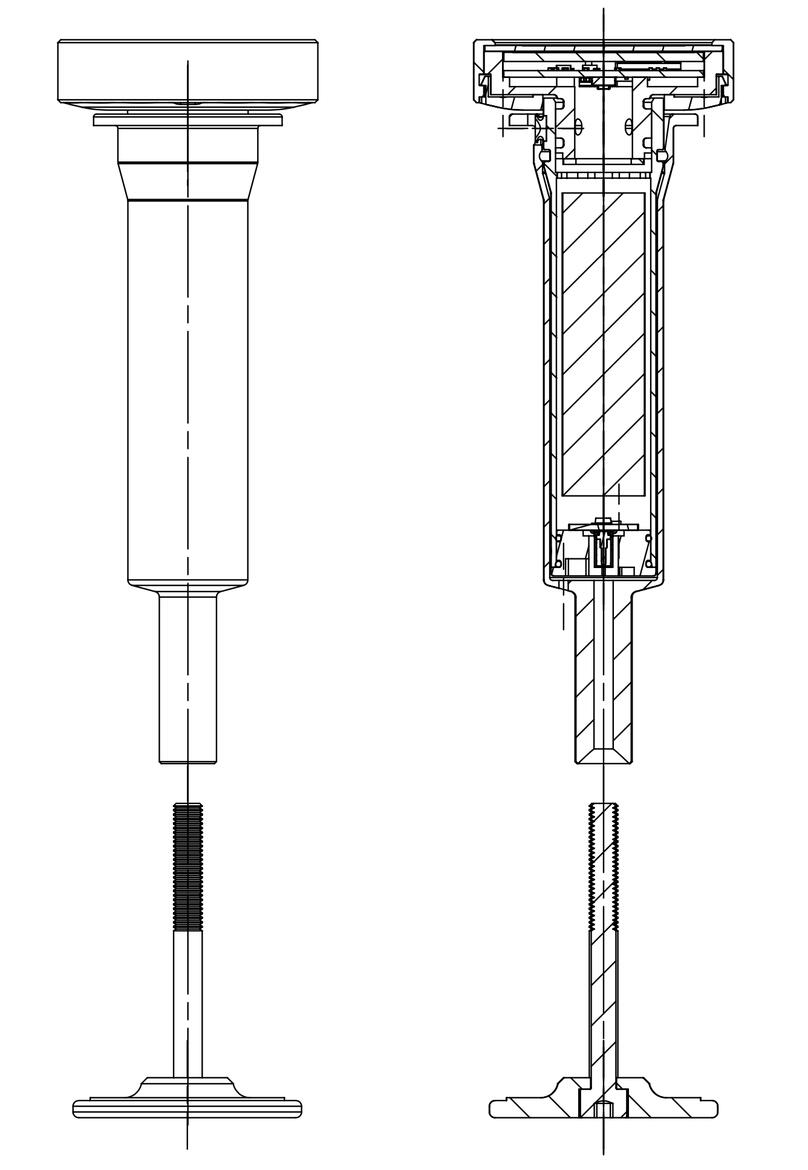

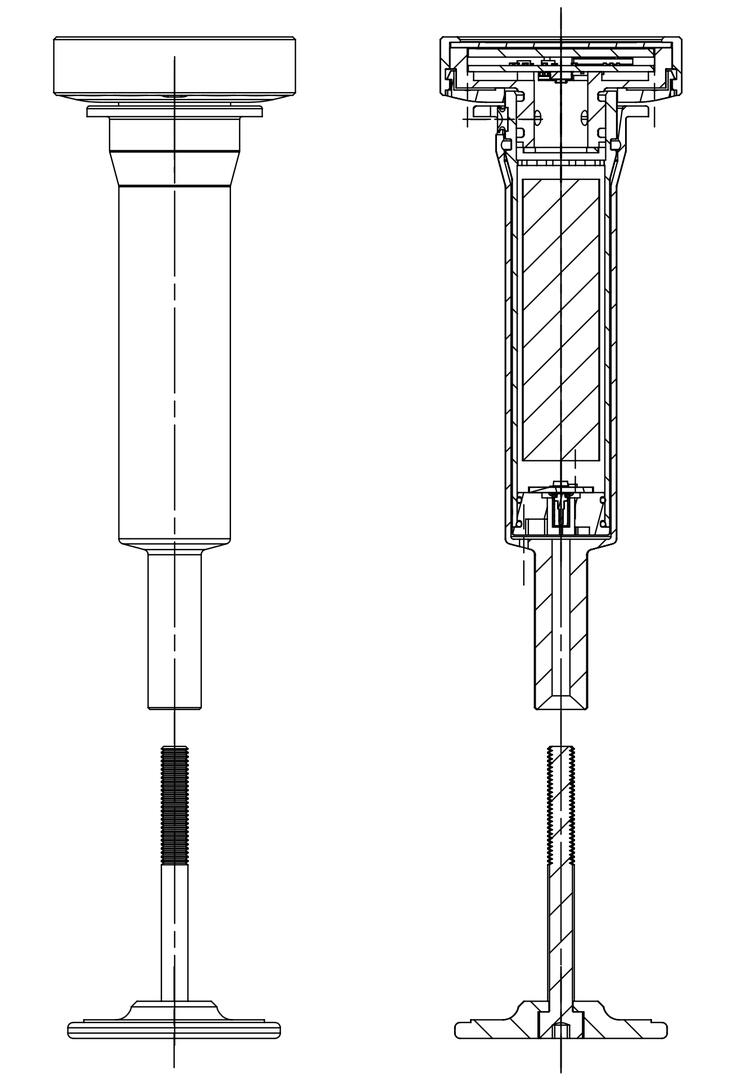

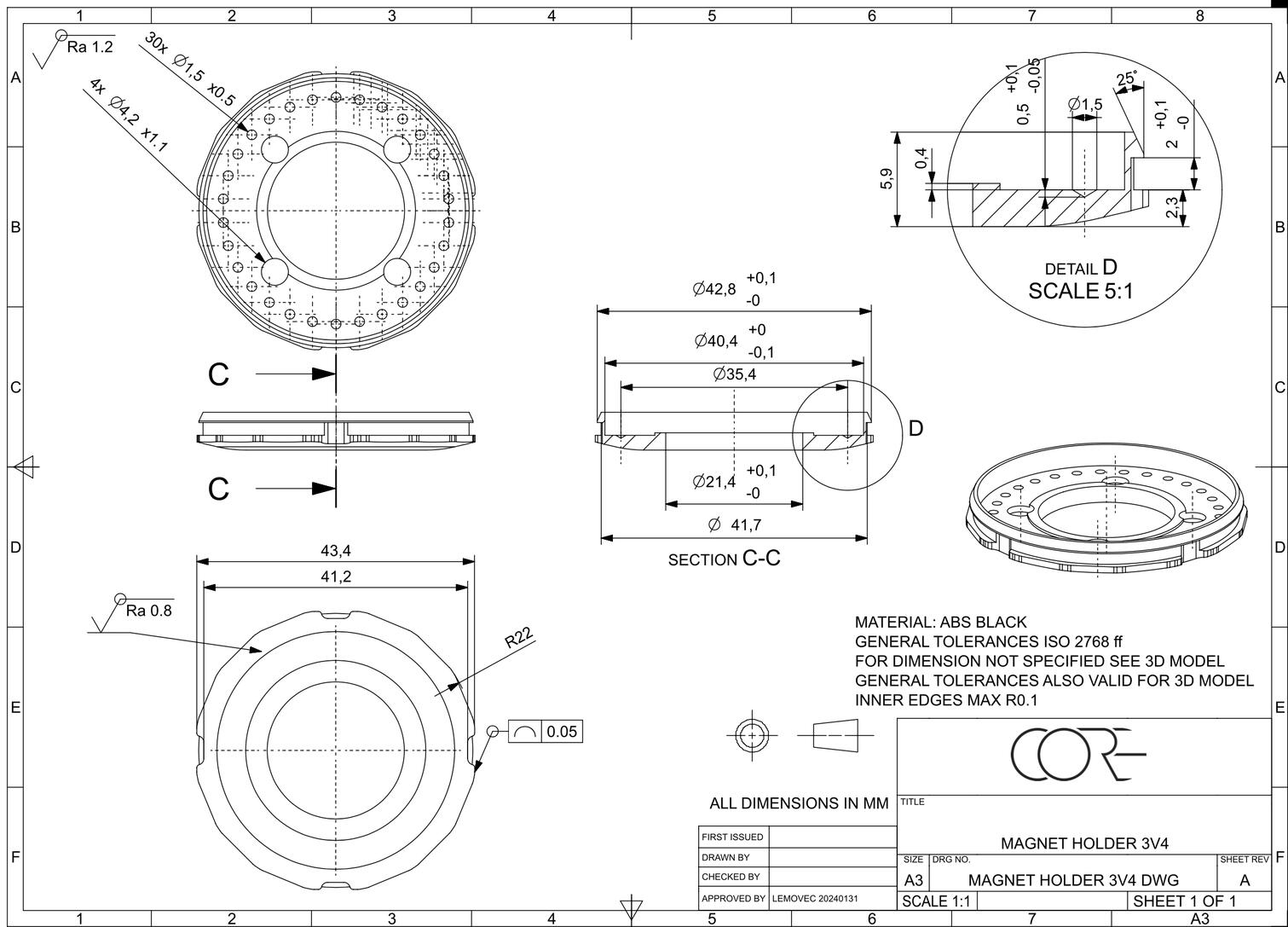

CoreCap is a next generation bike computer that fits into the steerer tube of your bike. Seamlessly integrated, protected & connected.

Services

Transforming innovative ideas into high-quality consumer products.As a product designer and developer with a strong background in mechanical engineering, I offer a wide range of services to bring your ideas to life. These services are designed to support every stage of your product development journey, ensuring innovative, high-quality, and market-ready solutions.

Design Research In-depth market and user research to identify needs, trends, and opportunities, ensuring your product is relevant and competitive.

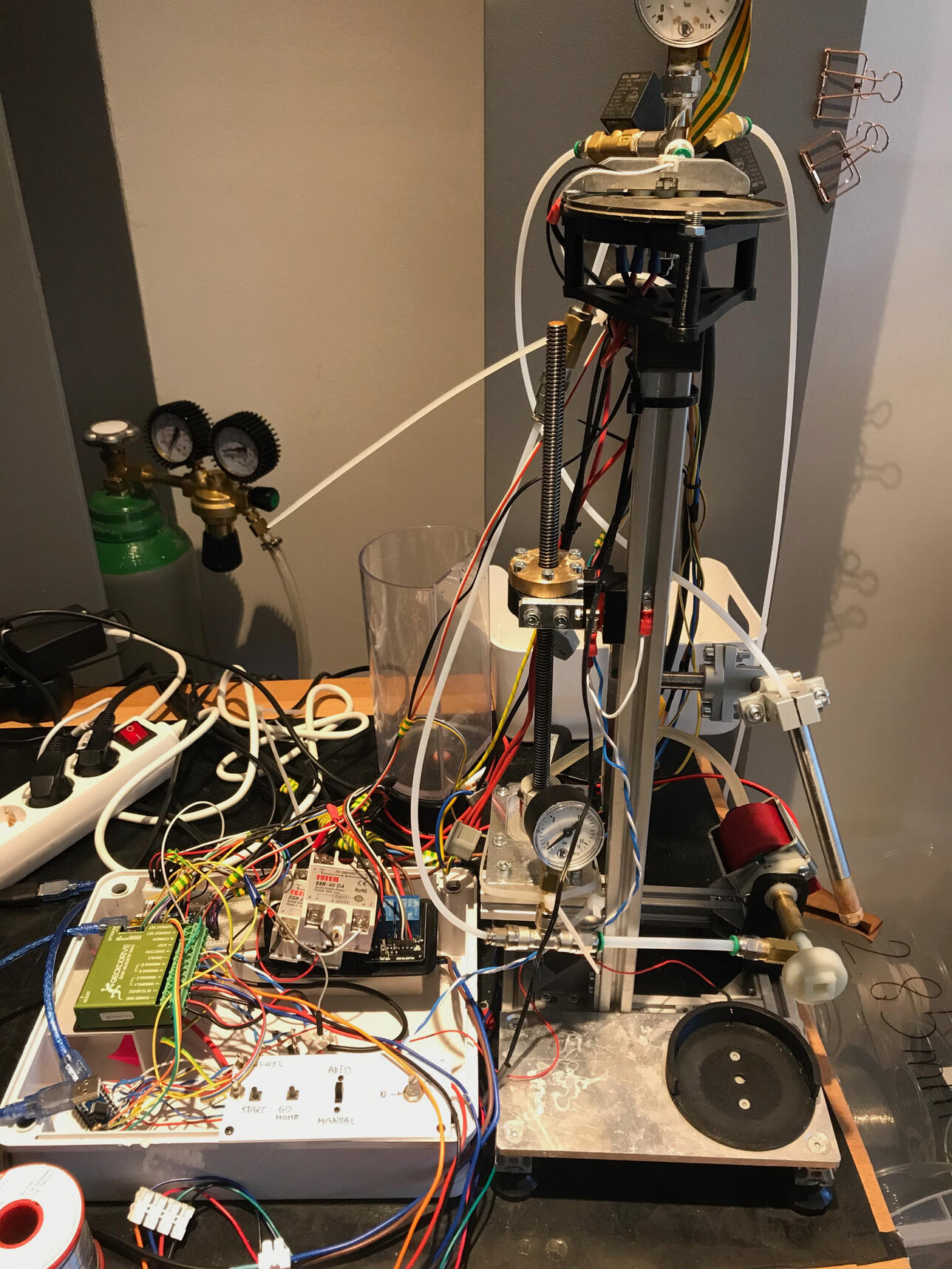

Prototype Design Development of functional and aesthetic prototypes to test and refine product concepts, ensuring optimal performance and user experience.

3D Printing Rapid prototyping and production using 3D printing technology to reduce development time and costs.

Computer-Aided Design (CAD) Advanced 3D modeling and simulation to visualize, analyze, and perfect designs before production.

Design for Manufacturing/Assembly (DFMA) Optimization of designs for cost-effective and efficient manufacturing and assembly processes, reducing production time and costs.

Industrialization Streamlining the transition from prototype to mass production, ensuring scalability and quality control.

Consultancy Expert advice and strategic guidance throughout the product development lifecycle, from concept to market launch.

Sustainability Consulting: Integration of eco-friendly materials and processes to create sustainable products that meet environmental standards.

Product Lifecycle Management: Comprehensive management of the product's lifecycle, from initial concept through to end-of-life, ensuring continuous improvement and adaptation.

Technical Documentation Creation of detailed technical documentation and user manuals to support product use, maintenance, and compliance with industry standards.

Let’s Work TogetherReady to bring your product idea to life? Contact us today for a free consultation.

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and we will contact you about beginning the proposal process.

81 CAP

81fatcap.com2024The world's fattest spray cap was developed in response to user feedback seeking better paint coverage. Comprehensive CFD analysis was used to define the final design, optimizing fluid flow and spray patterns. Multiple prototypes were produced and rigorously tested for line width, efficiency, and durability. Special consideration went into material selection, as the surface energy of the materials significantly contributed to the cap's performance and efficiency. Each prototype underwent extensive testing to ensure consistent performance, with caps enduring up to 30 uses. This development process has culminated in a product that not only elevates the efficiency of application but also expands the creative capabilities of graffiti artists, establishing new benchmarks in the field.

FGR valentin-home.com

2023The Food Garbage Recycler was developed with a strong focus on Design for Manufacturing and Assembly (DFMA). Its design ensures seamless integration into modern kitchens, fitting compactly under the sink. An efficient separation mechanism for food waste, water, and oil was engineered, with compartments designed to hold 14 days of food waste and a year's worth of oil, minimizing user maintenance. Durable, eco-friendly materials suitable for various manufacturing techniques were selected to ensure sustainability and longevity. By simplifying the assembly process, manufacturing costs were reduced and reliability was enhanced. The device is designed for easy disassembly, facilitating user maintenance. Extensive testing ensured compliance with environmental regulations by not flushing waste down the drain. This development showcases the creation of a practical, user-friendly, and eco-conscious solution for everyday problems.

Lumu Power

lu.mu

2015Lumu Power, a digital incident color and light meter, was developed as a result of a successful crowdfunding campaign. My mechanical engineering expertise as a product designer helped ensure the product's functionality, durability, and manufacturability. Leading the design exploration, I prioritized mechanical integrity and performance.

Throughout the design phase, I applied mechanical engineering principles to optimize Lumu Power form factor and ergonomics, enhancing user experience. I collaborated closely with manufacturing partners to streamline production workflows and ensure seamless integration of mechanical components.

I contributed to the development of comprehensive technical documentation, detailing assembly instructions and usage guidelines, which was essential for enhancing both manufacturability and usability. Lumu Power emerged as a robust, reliable solution, meeting the stringent demands of enthusiasts, professionals, and students.

CoreCap

corebikecomponents.com

2022The CoreCap project represents a significant innovation in cycling technology as the world's first integrated bike computer. Successfully crowdfunded, this compact device has set a new standard in the integration of biking and technology. My role involved leading the electrical, mechanical, and industrial design teams to develop a product that is both cutting-edge and highly functional.

CoreCap unit is engineered to endure high cyclical stresses and withstand environmental challenges such as water and dirt. This durability ensures continued performance and reliability even under harsh conditions. The design's robust architecture allows for the seamless integration of its electrical and mechanical components, providing a streamlined user experience without compromising on functionality or durability.

The successful launch of CoreCap through a crowdfunded campaign highlighted its uniqueness and the strong demand for an integrated, resilient, and compact bike computer in the market.

Let’s Work Together

Further case studies and services available upon request. Please provide some information on your project or goals and we’ll move the conversation on from there.

The importance of design research in product development

Design research is essential for developing products that meet market needs and stand out from the competition. By understanding user behaviors, market trends, and industry opportunities, I provide comprehensive design research services to guide your product development process.Design research services include:Market analysis: Conducting an in-depth study of market trends, competitor products, and industry developments to inform your product strategy. This helps identify what is currently successful in the market and where there are opportunities for new products.

User Research: Gathering insights from potential users through methods such as interviews, surveys, and usability testing. This ensures that your product addresses real user needs and preferences, enhancing user satisfaction and adoption.

Opportunity Identification: Identifying gaps in the market and potential areas for innovation. By understanding unmet needs and emerging trends, we can develop products that offer unique value propositions.By leveraging design research, you can create products that are not only innovative but also highly relevant and competitive in the market. Contact me to discuss how design research services can support your product development journey.

The power of 3D printing in product development

3D printing, or additive manufacturing, is transforming product development by enabling rapid, flexible, and cost-effective creation of prototypes and components directly from digital designs.Rapid Prototyping

3D printing dramatically shortens the time required to produce prototypes, allowing to quickly test and refine concepts. This rapid turnaround fosters more iterations and improvements, keeping projects on track in fast-paced markets.Design Flexibility

This technology supports the creation of complex and intricate geometries that traditional methods cannot achieve. With a variety of materials available, including plastics, metals, and ceramics, 3D printing broadens design possibilities and applications.Cost Efficiency

For small-scale production or customized components, 3D printing can be more cost-effective by eliminating the need for expensive molds and tooling, and minimizing material waste.Customization

3D printing excels at producing personalized products tailored to specific needs, especially valuable in healthcare for custom medical devices and implants.Accelerated Time-to-Market

By streamlining prototyping and testing, 3D printing reduces the time to bring products to market, allowing companies to respond swiftly to market demands and trends.Benefits of 3D PrintingSpeed: Rapid prototype and component production.

Flexibility: Creation of complex and innovative designs.

Cost Efficiency: Lower costs for small-scale and customized production.

Customization: Tailored solutions for specific needs.

Market Agility: Faster product launch times.3D printing revolutionizes product development by enhancing innovation, reducing development times, and delivering high-quality, market-ready products efficiently.Contact me for 3D printing servicesLeverage the power of 3D printing to bring your innovative ideas to life. Whether you have questions about 3D printing or need a quote for printing your object, contact me to discuss how 3D printing services can support your project.

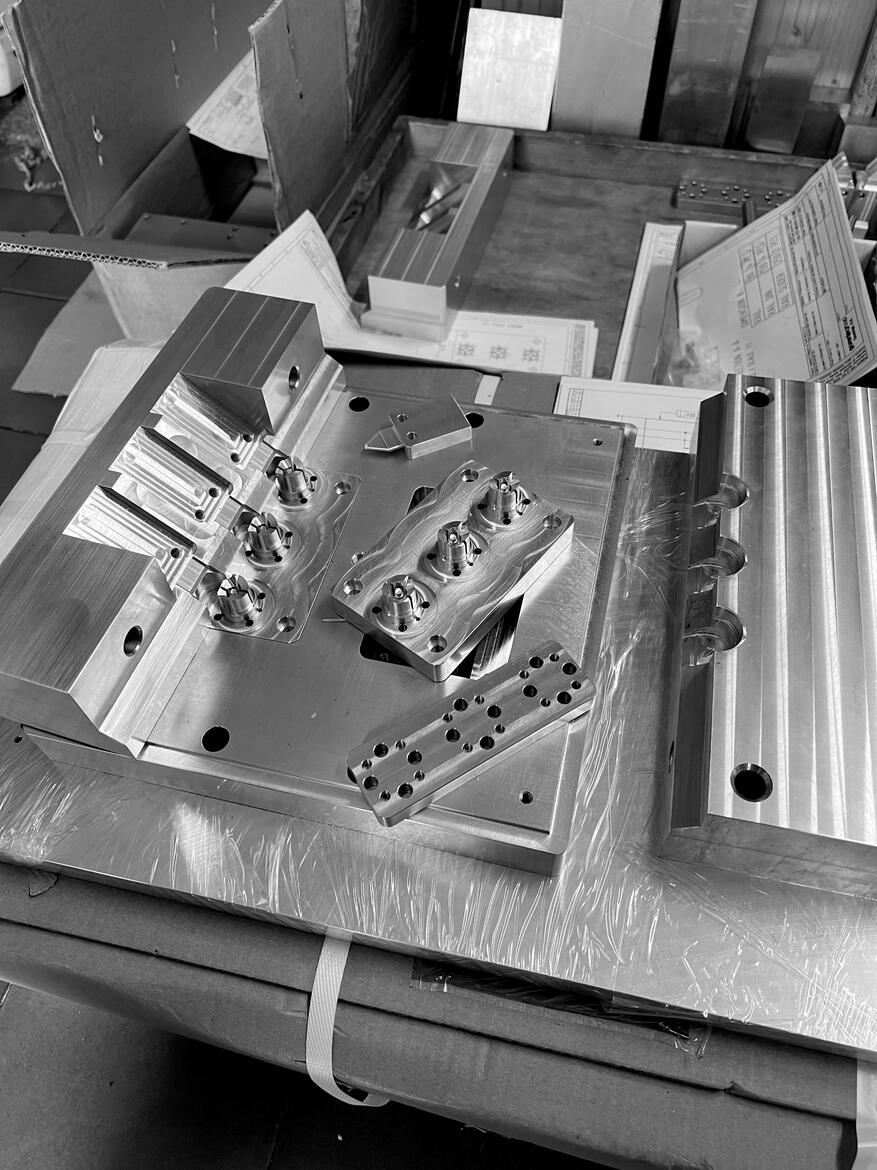

Prototype design: Bridging ideas and reality for your product

Prototype design is a critical phase in product development, transforming conceptual ideas into tangible models that can be tested and refined. As a product designer, I offer comprehensive prototype design services to help you bring your vision to life, ensuring your product is functional, user-friendly, and market-ready.How I can help you with prototype designConceptualization: We start with your ideas, creating initial sketches and digital models using computer-aided design (CAD). This step helps visualize your concept and sets the foundation for the prototype.

Creation: Using a variety of materials and 3D printing, CNC machining or other technologies, I develop physical prototypes. These can range from simple, low-fidelity models to high-fidelity, fully functional prototypes that closely resemble the final product.

Testing: The prototype undergoes rigorous testing to evaluate its design, functionality, and user interaction. This phase is crucial for identifying any issues and gathering valuable feedback.

Refinement: Based on the test results and user feedback, I refine the prototype, making necessary adjustments to optimize performance and user experience.Benefits of prototyping servicesRisk Reduction: Early identification and resolution of potential issues significantly reduce the risk of costly errors during mass production.

User Feedback: By allowing for user testing and feedback, we ensure that the final product meets consumer needs and preferences.

Innovation: The iterative process of prototyping fosters innovation, enabling experimentation with new ideas and solutions.Why choose my servicesExpertise: With a strong background in mechanical engineering and product design, I bring technical knowledge and creative insight to every project.

Advanced Tools: Utilizing the latest in prototyping technologies, I ensure precise and efficient development of your prototypes.

Collaboration: I work closely with you throughout the process, ensuring that your vision is accurately translated into a market-ready product.Let’s turn your innovative ideas into reality. Contact me to discuss how we can develop a prototype that perfectly aligns with your goals and sets the stage for a successful product launch.

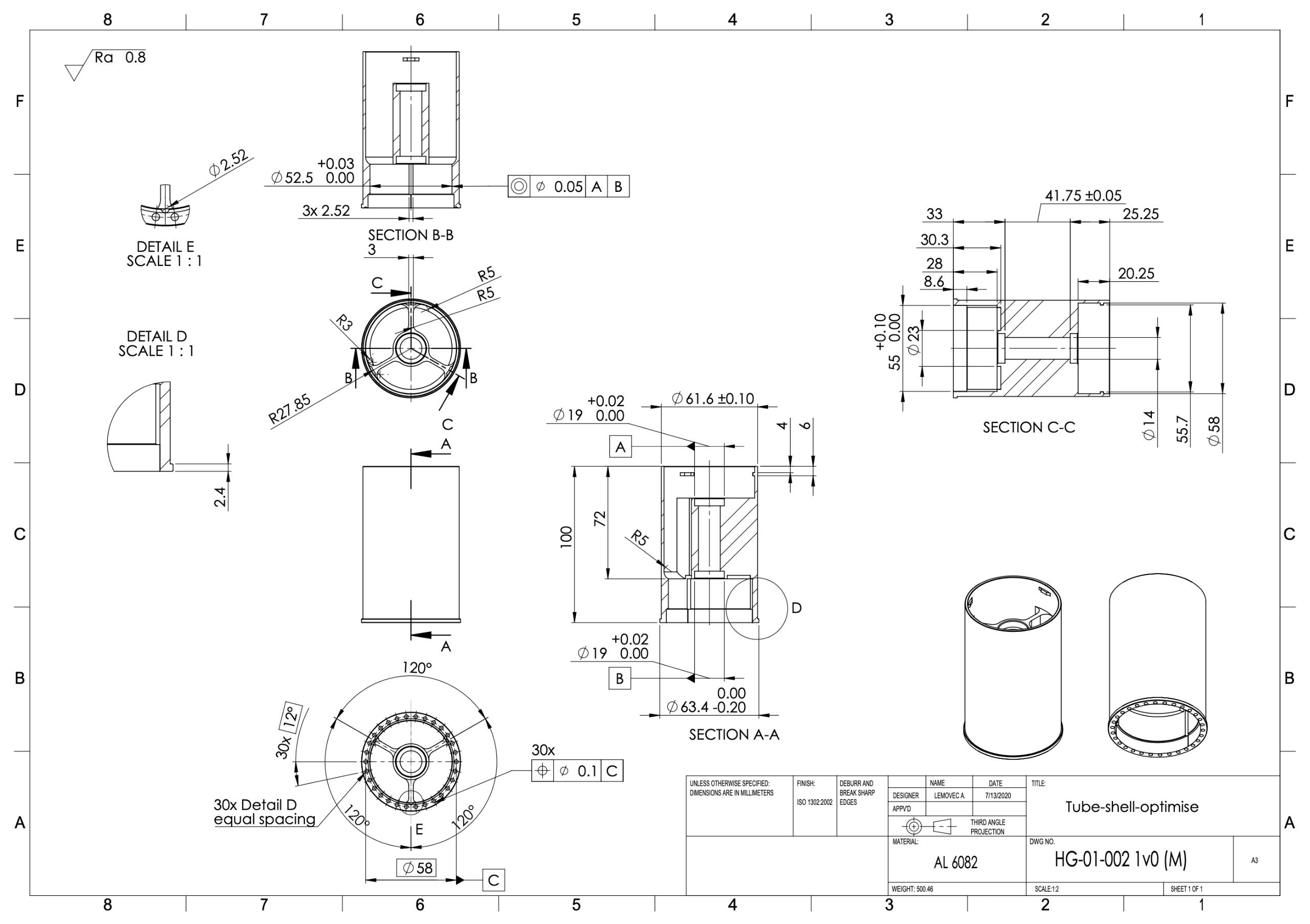

Enhancing product development with CAD

Computer-Aided Design (CAD) is a vital tool in modern product development, allowing for detailed and accurate 3D modeling. As a product designer with a mechanical engineering background, I offer CAD services to help bring your ideas to life efficiently and effectively.CAD services include:3D modeling: I create detailed 3D models of your product concepts using advanced CAD software. These models help visualize and refine your ideas.Simulation and analysis: CAD tools allow for simulation of real-world conditions, helping to optimize the design for performance and usability before moving to physical prototypes.Precision design: CAD ensures high precision, reducing errors and enhancing the accuracy of the final product.Efficient revisions: CAD allows for easy modifications and quick adjustments to design changes, speeding up the development process.Manufacturing support: CAD models provide essential data for manufacturing, ensuring a smooth transition from design to production.Why work with me?Expertise: I have a strong background in mechanical engineering and product design.

Tailored solutions: I customize my services to meet your specific needs, ensuring your product design is functional and manufacturable.

Collaborative approach: I work closely with you to ensure your vision is accurately realized.If you’re looking to enhance your product development process with precise and efficient CAD services, get in touch today to see how I can help.

Streamlining production with DFMA

Design for Manufacturing and Assembly (DFMA) is essential for optimizing product designs for efficient and cost-effective production.

As a product designer with expertise in mechanical engineering, I offer DFMA services to help you streamline your manufacturing process.Design optimization: I refine your product designs to simplify manufacturing and assembly, reducing production time and costs.

Material selection: I help choose the best materials to enhance performance and manufacturability.

Cost reduction: By improving design efficiency, I help lower production expenses and minimize waste.

Quality enhancement: Optimized designs lead to higher quality products with fewer defects and better reliability.

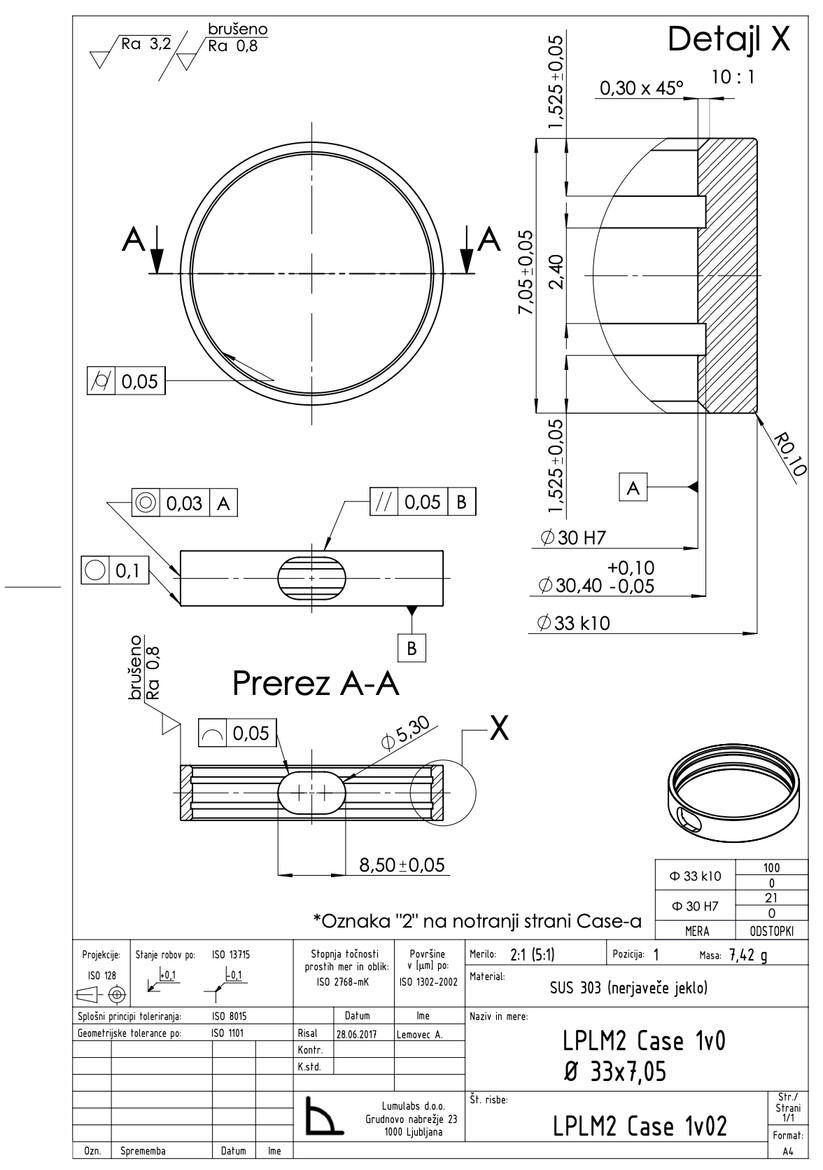

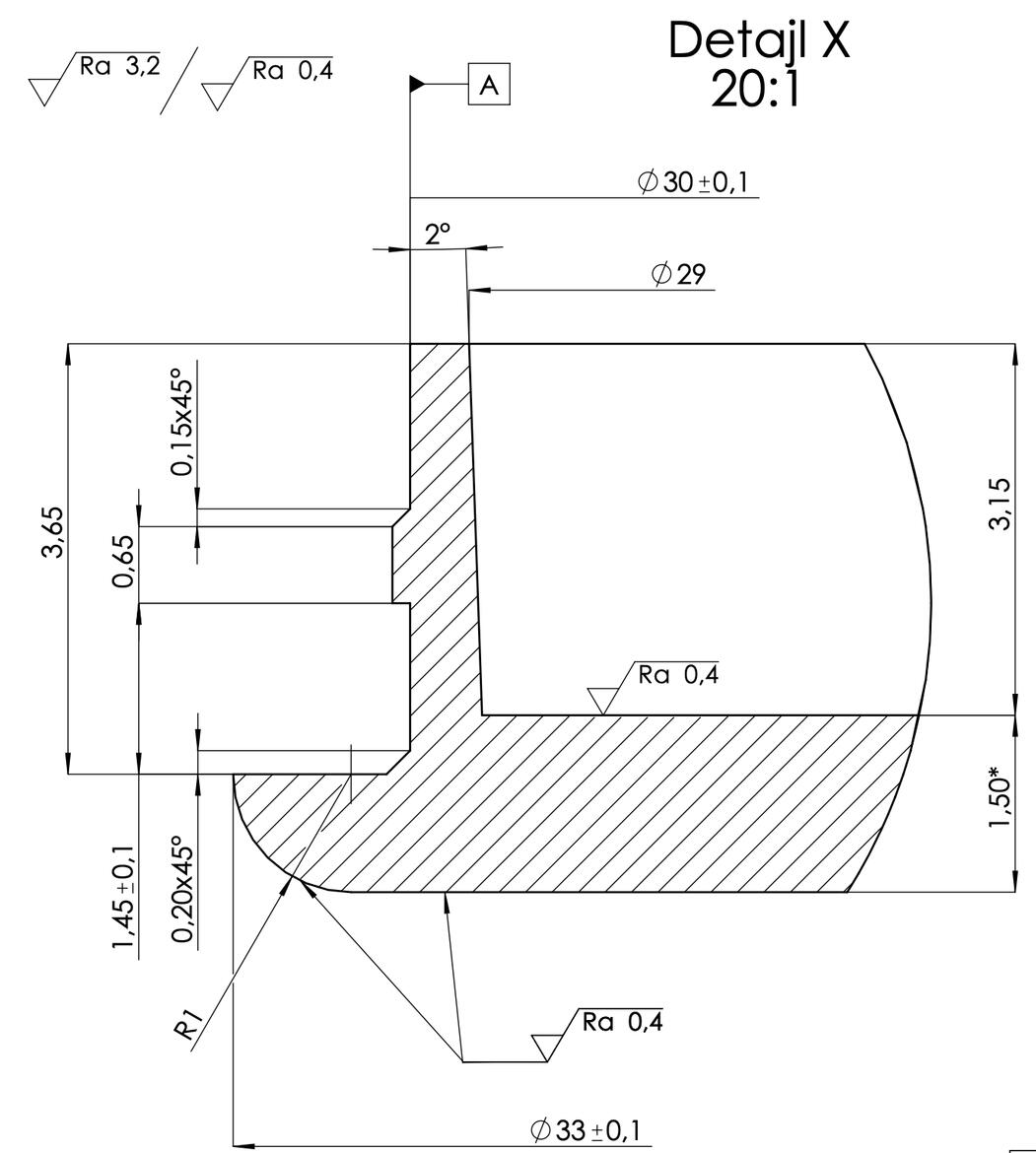

Technical documentation

Technical documentation is a vital component of product development, providing detailed and precise information about parts and assemblies. As a product designer with expertise in mechanical engineering, I offer specialized services in creating technical drawings that adhere to international standards, ensuring accuracy and consistency throughout the production process.Technical documentation services:Detailed technical drawings: I create comprehensive technical drawings for individual parts and assemblies, capturing every detail necessary for manufacturing. These drawings include dimensions, tolerances, materials, and finishes, ensuring that every aspect of the design is clearly communicated.Standardization according to ISO: All technical drawings are standardized according to the International Organization for Standardization (ISO) guidelines. This ensures that the documentation is consistent, universally understood, and compliant with global industry standards.Assembly instructions: I develop detailed assembly instructions that illustrate how parts fit together, step-by-step. These instructions include exploded views, sequential diagrams, and annotations, making the assembly process straightforward and efficient.Bill of Materials (BOM): Each set of technical drawings is accompanied by a Bill of Materials, listing all components, sub-assemblies, and materials required for production. This document ensures that every element is accounted for, facilitating efficient procurement and assembly.Quality control documentation: I provide documentation that supports quality control processes, including inspection criteria, testing protocols, and acceptance standards. This ensures that all parts and assemblies meet the specified requirements and maintain high quality.Revision control: Documentation includes a system for tracking revisions and updates, ensuring that any changes to the design are clearly documented and communicated. This helps maintain consistency and accuracy throughout the product lifecycle.